XRF Cowboys vs Experts

In the world of catalytic converter trading, it seems like everyone is armed with an XRF gun, zapping samples and offering prices left and right. This article addresses both the buyers who run the risk of mispricing samples and the sellers who may fall victim to undervaluation, resulting in a significant loss on their converters.

Let’s start with the basics. Catalytic converters begin as ceramic substrate, manufactured by companies like Corning. These substrates are durable, have a large surface area, and, most importantly, do not contain Precious Group Metals (PGMs).

The ceramic substrates are then loaded with PGMs by catalytic converter manufacturers. The amount of PGMs varies depending on the car type and the target market for the converters.

The primary function of catalytic converters is to lower the activation energy required for the complete combustion of various gases during the combustion process. Manufacturers use PGMs sparingly and optimise their usage to minimise costs while meeting emission standards.

It’s important to note that PGM concentration is typically higher toward the centre of the ceramic substrate, with potentially zero loading of PGMs at the edges.

To obtain accurate results, a comprehensive process is required. This involves disassembling the entire converter, crushing and milling the monolith to a specific size, homogenising the material, and ensuring thorough mixing within acceptable limits. Simply using an XRF gun to scan chunks of a monolith is inadequate and can lead to misleading readings.

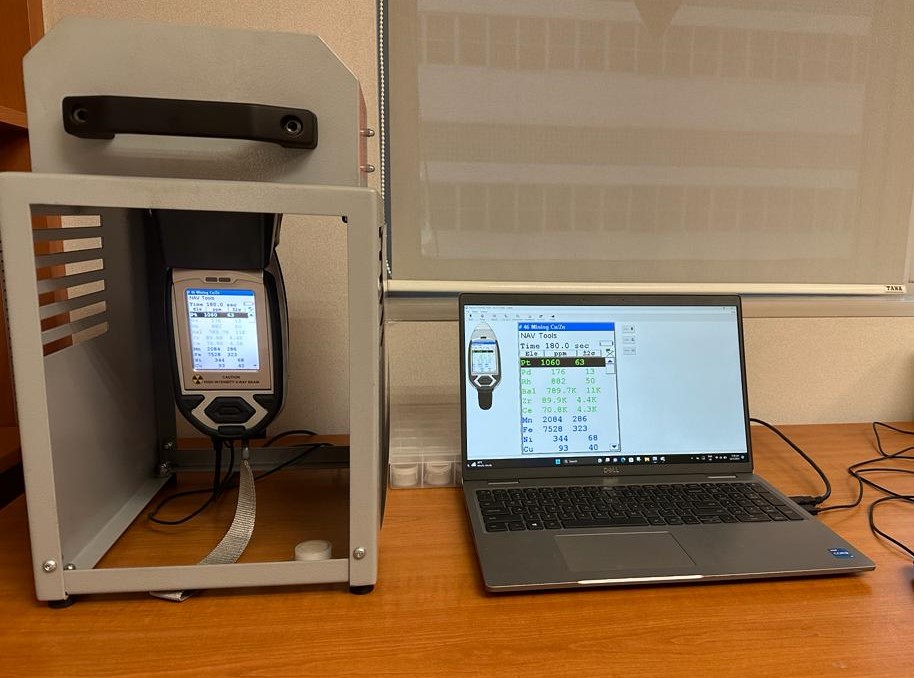

Several factors need to be considered for accurate readings. Firstly, readings can vary significantly at different points, especially without proper milling and homogenization. Running the XRF gun for a longer duration allows readings to stabilise. Additionally, using an XRF cup with a protective film is crucial to prevent the interference of dust or contaminated particles from previous tests, which can affect the results.

Calibration is equally critical. XRF machines are typically calibrated for alloys and metals with high concentrations, usually represented in percentages. However, catalytic converters contain much lower concentrations of PGMs, typically ranging from around 100 ppm to 2,000 ppm. Calibration for catalytic converters is essential to ensure accurate readings. Some companies offer machine calibration services and provide calibration certificates.

It’s important to note that XRF machine calibration has limitations. The calibration curve may be limited to a certain range, such as up to 1,500 ppm or 2,000 ppm for Pt and Pd, and 300-500 ppm for Rh. Readings beyond the calibration range should be interpreted with caution, as they may be lower than the actual values.

In cases where readings exceed the calibration range, a dilution process can be applied. Dilution requires meticulous handling of known samples and an understanding of the associated mathematics. Exercise caution when readings fall beyond the calibration limit.

Furthermore, some additives of certain metals can be mistakenly identified as Pt or Pd by the XRF gun. These additives, when crushed and scattered onto samples, may yield higher readings than normal. To prevent imitation of similar fraudulent acts, specific details of these additives are intentionally omitted, highlighting the need for buyers to remain vigilant.

There are instances where Pt and Pd readings may be swapped or combined. Further analysis, including considering the presence of other metals, is necessary to verify the accuracy of the analysis beyond Pt, Pd, and Rh. Understanding the matrix of the materials present is also crucial, as calibration methods are specific to different material matrices.

We have encountered cases where buyers in Europe purchased several thousand kgs of catalytic converter ceramics with XRF readings of 3,000 – 4,000 ppm of Pt, only to discover through ICP analysis that it held almost zero value. These buyers fell victim to scams involving the addition of additives that appeared as Pt on the XRF machine, deceiving inexperienced XRF gun users. Buyers and sellers alike, it’s important to stay alert.

The XRF gun is a valuable tool, but understanding its limitations and capabilities is crucial. While it can provide reliable results most of the time, mistakes can be extremely costly. So, are you an XRF cowboy, or do you truly understand what you’re doing?

Like, share, and follow us for more informative articles.

Disclaimer: This blog is solely for informational purposes. These opinions and views are not representative of the people or organisations discussed. All information posted to this blog and any links provided are not guaranteed to be accurate or effective, and we will not be held liable for any errors in this information. There is no intention to offend any individual, brand, or institution with this blog.