Impact of EV Cars on Catalytic Converter Recycling

The rapid adoption of electric vehicles (EVs) is poised to profoundly impact the catalytic converter recycling industry. EVs eliminate the need for catalytic converters as they do not rely on internal combustion engines. Consequently, the increasing popularity of EVs is expected to decrease the demand for vehicles with traditional engines, potentially reducing catalytic converter production and affecting the recycling industry.

However, it’s important to recognize that many hybrid vehicles still utilise internal combustion engines and, therefore, require catalytic converters. Additionally, various countries have implemented regulations mandating the installation of catalytic converters in vehicles to mitigate emissions. Hence, while the market for conventional cars may diminish, there is likely to remain a demand for catalytic converters in hybrid vehicles and for retrofitting older vehicles to meet emission standards.

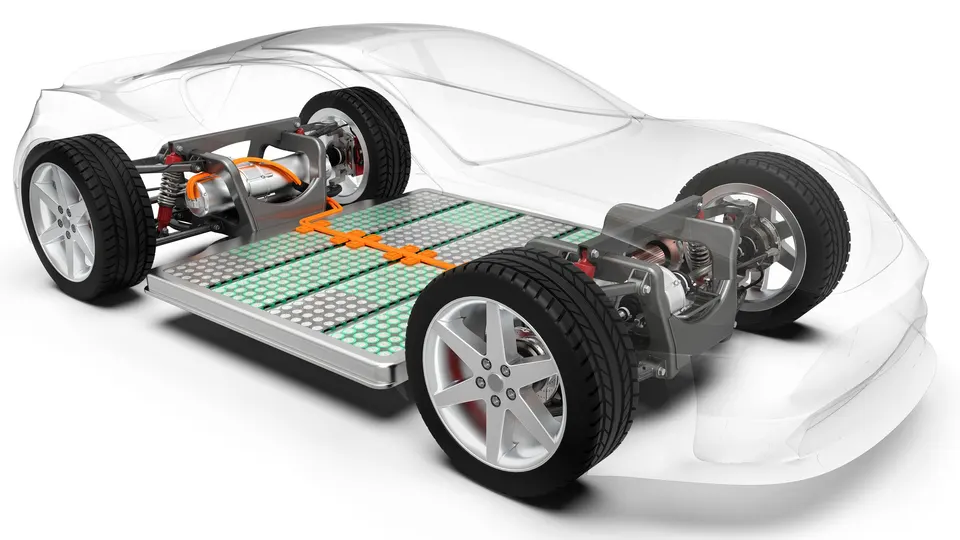

Furthermore, the surge in battery demand for powering EVs is projected to drive significant growth in the need for metals like nickel, cobalt, and lithium, which are essential raw materials for battery production. This increased demand may substantially raise the prices of these metals, making the recycling of catalytic converters even more attractive.

Image by Jim Gorzelany on www.forbes.com

Nevertheless, manufacturers continue to engage in an ongoing race to develop superior battery technology for EVs, with companies like Tesla leading the charge. Since consumers are generally accustomed to Internal Combustion Engines (ICE) vehicles, EV batteries must meet several key criteria. They need to offer fast charging capabilities, similar to the convenience of refuelling with petrol or diesel, with charging times of approximately 3-5 minutes. Additionally, they must provide an extended range, ideally covering 600 to 1,000 kilometres and beyond on a single charge, to alleviate range anxiety and enable long-distance travel. Furthermore, EV batteries need to have a long lifespan, lasting for at least 10 years or the entire vehicle lifespan, to eliminate the need for frequent battery replacements. However, it’s important to note that EV battery cells can degrade over time, resulting in reduced efficiency and maximum charge capacity each year.

Realistically, thoroughly researching, testing, developing, and bringing to the mass market EV batteries that meet all these demanding requirements while remaining cost-effective for competitive pricing compared to ICE vehicles will take several years, at a minimum.

To provide a broader perspective, let’s consider some figures related to global motor vehicle production. Currently, there are approximately 1.45 billion vehicles worldwide, with around 80 million vehicles manufactured each year based on 2022 data. This suggests a replacement rate of approximately 5.5%. Out of the newly manufactured vehicles, around 10.5 million are EVs, accounting for approximately 13.1% of the replacement vehicles or roughly 0.7% of the overall replacement rate.

Another challenge faced by electric vehicles (EVs) is the inadequate charging infrastructure. While smaller and wealthier countries may swiftly develop EV charging networks with government intervention and funding, many developing countries might experience slower adoption of this new technology. Building a critical mass of charging infrastructure is crucial for the widespread adoption of EVs. However, governments might hesitate to invest in such infrastructure for a small initial adoption rate, especially when faced with more immediate and pressing needs. Furthermore, in less developed countries, the accessibility of charging infrastructure may be limited to wealthier demographics.

Consequently, the necessity of a significant initial investment in charging infrastructure could pose a barrier, particularly in less developed countries where priorities differ significantly. Therefore, it is likely that EVs and internal combustion engine (ICE) vehicles will coexist for a considerable period of time.

Overall, while the adoption of EVs will impact the catalytic converter recycling industry, predicting the precise nature and extent of this impact is challenging. It will depend on various factors, including government regulations, consumer preferences, and technological advancements, as previously highlighted.

Considering the vast number of vehicles that need replacement and the obstacles that must be overcome, the pace of EV production will inevitably increase in the future, but there is still a very long road ahead.

Skrya, with expertise in recycling both precious and base metals, is well-positioned to potentially collaborate with customers involved in catalytic converters and potentially engage in EV battery recycling.

Remember to like, share, and follow us for more articles.

Disclaimer: This blog is solely for informational purposes. These opinions and views are not representative of the people or organisations discussed. All information posted to this blog and any links provided are not guaranteed to be accurate or effective, and we will not be held liable for any errors in this information. There is no intention to offend any individual, brand, or institution with this blog.