Dangers Selling Lots to Middlemen!

When catalytic converters are sold on an assay or toll refining basis, sellers are paid based on the metal content of the converters, rather than a fixed price per unit. This is generally done by sending the converters to a refiner, who will then analyse the metal content and pay the seller based on the value of the metals extracted.

Most, if not all, of the larger recyclers of catalytic converters — those who recycle in excess of several thousand units — would sell on an assay basis. On the other hand, a lot of the smaller recyclers who typically do an estimate of 300 to 5,000 units are selling to Middlemen Companies (MCs) that are purporting to do their own sampling and analysis. Best of all, these MCs settle with their customers on an assay basis, based on their own equipment.

Image by www.agrianusandhan.co.in

Many such MCs consider this as an advantage and would market this feature prominently. Some MCs do know what they are doing. However many of them don’t. One should really consider the following factors first before deciding on sending your materials to them.

MCs would eventually have to send their own materials to refiners for sampling and analysis. Herein lies the biggest problem. With a Chemical Engineering background and having run both a full bulk sampling facility, XRF and ICP laboratories for many years, we can attest that getting this done correctly is a huge endeavor.

Given the complexity of the above processes, the MCs are therefore subject to the risk that the final assays from the refiners might even be lower than the results they give to their own customers whom they have already fully settled and closed deals with. This, of course, would not be sustainable and the workaround would be to simply give their customers a haircut/shave, a safety margin — or whatever term you’d rather use — so as to give themselves some leeway in the event things don’t work out for them. Some just do an outright markdown of the analysis of the customer’s catalyst samples.

Moreover, there are many things these guys with their glorified machines may overlook.

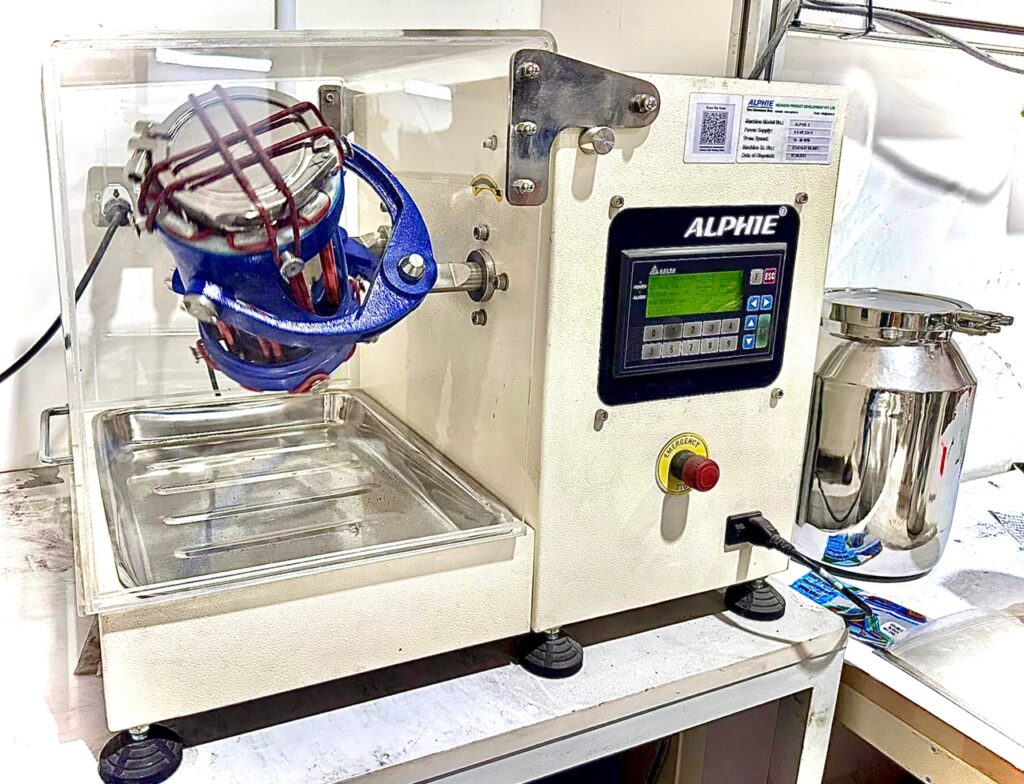

Firstly, the bulk sampling system. To draw a parallel, here’s a picture of a Homogeniser used on a laboratory scale for individual converters.

We mix small samples weighing between 0.5kg and 2.0kg in a 10-litre container for approximately 1.5 hours. After which, we still do parallel samples and conduct analysis. Samples taken at various random points may still display significant concentration differences. This situation might occur despite several hours of mixing. In such instances, the samples would require further mixing.

Now imagine a typical lot size of 1,000kg to 3,000kg. Can you imagine how long it would take to completely homogenise your materials? How can one be sure that the mixing is adequate? Would the samples obtained from this process be representative of your lot? Sampling systems rely on grinding the materials to a minimum particle size and assume good mixing. Several other sampling systems like a falling stream bulk sampling system remove the need for this homogeneity. That’s for another discussion since it uses a different methodology.

In the case of the ball mill which is one of the most common ones around, crushing them to a smaller size is one thing, how about if the samples are homogeneous? Are the MCs just handpicking several samples? Would the buyer take several samples, analyse them, and offer a ‘safe’ result to you? The question that beckons is that, is the final sample being tested, truly represents your lots, or is it under represented?

The sampling process produces dust with rich PGM content. Are the samples correctly extracted and added back in? How is the cleaning process between the 2 lots? Is your lot cross-contaminated with the previous lot? Are the MCs’ weighing scales calibrated? How do they handle the moisture test? Are there any international standards in place? Using XRF to settle is a no-no, but is their analytical equipment properly calibrated?

How about the ICP analysis? Do they take care of the steps required to maximise the precipitation of Rhodium? Some commercial laboratories are not aware of these steps. Only laboratories that specialise in catalytic converters are able to obtain the correct results.

Furthermore, the ‘good’ laboratories also run 2 ICP machines simultaneously to eliminate machine errors. Does your MC run 2 ICP machines to do parallel testing?

Have you checked if the PGM standards are within the expiry dates? These standards are fairly expensive and have to be used to calibrate the machines each time they are being run. Some MCs cut costs by using old or expired standards. There are many nuances that you ought to know.

Then there is integrity. Some MCs may not have the same level of integrity as refiners when it comes to accurately reporting the weight and metal content of the converters. This can lead to disputes and legal issues down the line if the sellers later discover that they were not paid accurately for the materials they sold. Some MCs blatantly change or lower the weight, increase moisture content to reduce payable weights and also change the analysis. There have also been cases of suits filed and proven against some of these MCs.

To avoid these risks, it is important for sellers to work with reputable refiners who have the necessary expertise and equipment to accurately assess the value of their converter lots.

At SKRYA, you can have the best of both worlds. We use our laboratory and analysis solely for the publication of individual converters’ analysis and prices on our Catalopedia application. For lots that require payment, we work directly with partner refiners and we adhere strictly to the refiner’s results for all sampling and analysis conducted on the materials.

This simply means you are protected. The results are as is, exactly. We don’t run any analysis risk, and you as a seller get the most accurate and true results. And if you wish to challenge the analysis due to a less-than-satisfactory outcome, we also have a challenge system in place in which you can verify the analysis with established, reputable 3rd parties as arbiters.

Don’t be caught off guard by the MCs’ quick turnaround in cash flow and quick analysis to get your money back. With margins thinning these days, getting the correct value to your materials is vital for the long-term sustainability and survival of your company.

Be mindful to check the MC’s capabilities and track records before putting your trust there. You can always check with us if you need any clarifications. Have any of these MCs misplaced your trust? Do you have any horror stories you want to share?

Like, share and follow us for more articles.

Disclaimer: This blog is for informational use only. Any views or opinions expressed are personal and do not reflect the people or organisations discussed. We do not guarantee the accuracy or effectiveness of any information posted to this blog and will not be held responsible for any errors in this information, nor through any provided links. This blog is not intended to offend any person, brand, or institution.